Pipes are manufactured according to the requirements of the following standards:

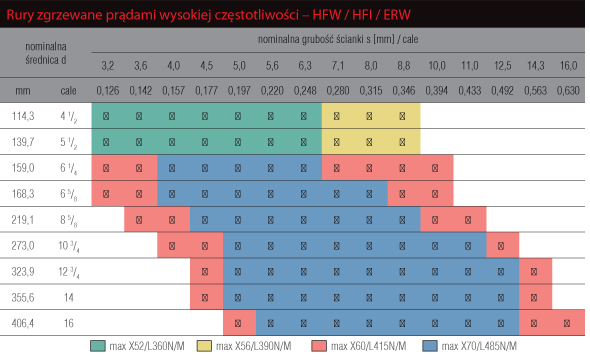

Pipes are manufactured in diameter range from 114,3 mm to 406,4 mm, in production lengths from 6 m to 18 m. Pipes are supplied with plain or bevelled ends, after hydrostatic test and automatic non-destructive ultrasonic or eddy current tests.

During production process the heat treatment is performed to eliminate stresses generated in the seam as well as to guarantee both homogenous steel structure and higher strength properties.

Depending on the required mechanical and technological properties or application, the pipes are produced from the following steel grades:

Upon the customer’s needs pipes are supplied as: bare – without protection coating, or with external three-layer polyethylene (PE) or polypropylene (PP) anticorrosion coatings and with internal either cement or epoxy lining. Against agreement pipes may be supplied with other anticorrosion protection e.g. galvanized pipes.

High frequency welded (HFW) pipes manufactured by “FERRUM” S.A. can be successfully used to produce steel fittings including tees, reducers, elbows and bends. Fittings are made by either cold or hot bending process depending on the strength parameters of steel grade as well as the diameter and wall thickness.

Application of welded pipes demonstrates the highest level of excellence in microtunneling, most modern “digging” technique used to construct small tunnels. Completing the microtunneling by application of steel welded pipes provides both minimum im- pact on environment and slight interference with ecological land management.

In 1999 the most modern production line of high frequency welded (HFW) steel pipes and structural hollow sections was commenced into operation. The line was designed by the German enterprise SMS Meer and has an annual production capacity of 120 000 Mg for the specified production mix.

Production programme of HFW / HFI / ERW pipes

Length of pipe from 6 m to 18 m

Norma / Standart |

Gatunek / Grade |

||||||

|---|---|---|---|---|---|---|---|

| API Spec 5L PSL2 | Grade B | X42 | X46 | X52 / X56 | X60 | X65 | X70 |

| PN–EN ISO 3183 | L245NE/BN L245ME/BM |

L290NE L290ME |

L360NE L360ME |

L415NE L415ME |

L450ME | L485ME | |

| PN–EN 10224 | L235 | L275 | L355 | ||||

| PN–EN 10217–1 | P235TR1/ TR2 | P265TR1/TR2 | |||||

| PN–EN 10217–2 | P235GH | P265GH | |||||

| PN–EN 10217–3 | P355N /NH | ||||||

| PN–EN 10219-1,2 | S235JRH | S275J0H S275J2H |

S355J0H S355J2H |

S460MH |

Upon agreement it is possible to deliver pipes according to any other standard or required specification

FERRUM S.A.

ul. Porcelanowa 11

40-246 Katowice, Poland

tel.: +48 32 730 47 99

fax: +48 32 730 46 77

email: ferrum@ferrum.com.pl